-

Macchina imballatrice dei sacchetti

-

Macchina imballatrice del granello

-

macchina imballatrice liquida

-

macchina imballatrice della polvere

-

Mini Doypack Packaging Machine

-

Macchina imballatrice della bustina di tè

-

macchina imballatrice del caffè

-

macchina imballatrice verticale

-

Macchina imballatrice di flusso

-

Stia sull'impacchettatrice del sacchetto

-

Macchina d'imballaggio sotto vuoto rotatoria

-

Macchina di rifornimento

-

Macchina imballatrice orizzontale di Doypack

-

Borsa di Premade

-

Accessori della macchina imballatrice

-

macchine per riempire e coprire

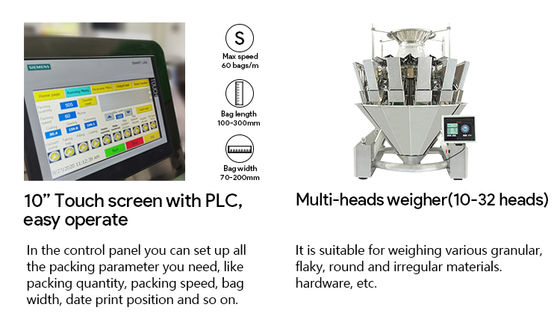

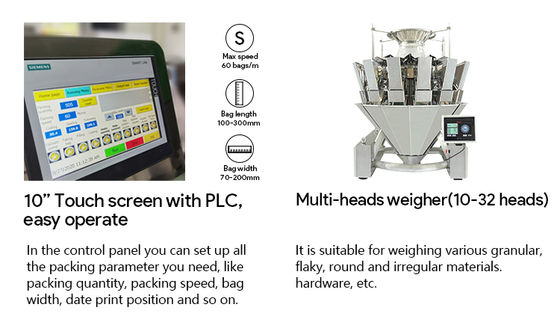

Eight-Station Beef Jerky Packaging Machine, 304 Stainless Steel, Food-Grade, Safe and Hygienic

| Luogo di origine | Guangdong , Cina |

|---|---|

| Marca | ZCHONE PACK |

| Certificazione | ISO,CE |

| Numero di modello | ZC-8200 |

| Quantità di ordine minimo | 1 set |

| Prezzo | $18000 |

| Imballaggi particolari | Packaging di custodia in legno di esportazione standard |

| Tempi di consegna | 15 |

| Termini di pagamento | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Capacità di alimentazione | 1/set/15 giorni |

Contattimi gratis campioni e buoni.

WhatsApp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

Se avete di preoccupazione, forniamo la guida in linea di 24 ore.

x| Tipo | Macchina di imballaggio automatico | Nome del prodotto | Food Granule Multi-Station Packaging Machine |

|---|---|---|---|

| Dimensione (L*W*H) | L1900*W1400*H1450 | peso (kg) | 1300 |

| Voltaggio | 110V 220V 380V 50Hz/60Hz | Capacità produttiva | 20bag/min, 50bag/min, 30bag/min |

| Evidenziare | 304 stainless steel beef jerky packaging machine,food-grade granule packing machine,hygienic eight-station packaging machine |

||

| Packing Machine Type | |

|---|---|

| Granule Packing Machine | |

| Liquid Packing Machine | |

| Powder Packing Machine | |

| Stand-Up Pouch Packing Machine | |

| Vertical Packing Machine | |

| Horizontal Packing Machine | |

| Tea Bag Machine | |

| Coffee Bean Packing Machine | |

| Horizontal Packing Machine |

Eight-Station Beef Jerky Packaging Machine, 304 Stainless Steel, Food-Grade, Safe and Hygienic

"Beef jerky packaging machine" is a highly specialized and specific field. Due to its characteristics (hardness, oiliness, irregular shape, etc.), beef jerky places special requirements on the packaging machine.

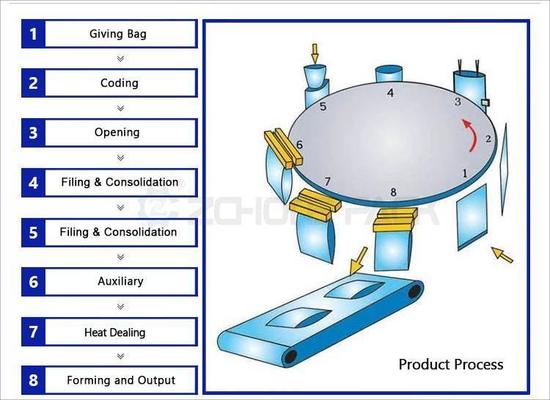

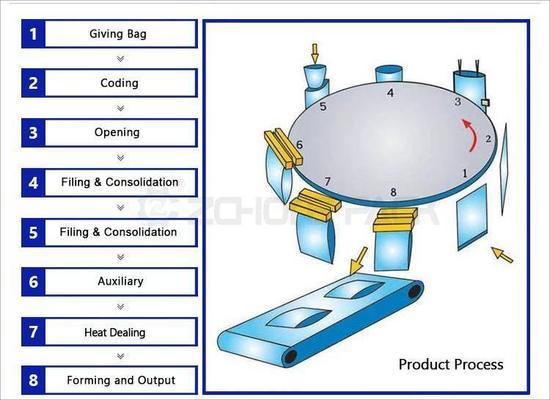

I. What is an Eight-Station Beef Jerky Packaging Machine?

"Eight stations" refers to the packaging machine having eight workstations (or work positions). These work positions are mounted on a rotating turntable. Each work position holds a pre-made packaging bag, which passes through various actuators sequentially as the turntable rotates, completing a series of packaging actions.

This is a fully automatic, high-efficiency packaging equipment, particularly suitable for packaging solid products like beef jerky that have a fixed shape and require vacuum or nitrogen-filled preservation.

II. What are the eight work positions responsible for?

Taking a standard eight-station bag-type packaging machine as an example, its workflow is typically as follows:

1. Work position one: Bag picking and opening

The robotic arm accurately picks up a pre-made empty bag from the bag compartment.

1. **Station Two:** Use suction cups or grippers to open the bag opening, preparing it for feeding.

2. **Station Three:** Bag Opening Detection (Optional)

A sensor detects whether the bag opening at the previous station was successful. If the opening fails, the machine skips the feeding process to prevent material spillage.

3. **Station Three:** Feeding

This is a crucial station for beef jerky packaging. Different feeding methods exist depending on the shape of the beef jerky:

Manual Feeding: Operators place weighed beef jerky (e.g., whole slices, large chunks) into the bag at this station. This is the most flexible method.

Automatic Feeding: Regularly shaped (e.g., granules, strips) beef jerky is automatically fed into the bag via a conveyor belt, vibrating plate, or robotic arm. This requires an automated weighing device (e.g., a combination scale) at the front end.

4. **Station Four:** Nozzle Closure and Finishing (Optional)

If a feeding nozzle is used, it will be removed here. The bag opening may also be finished to ensure a clean sealing area.

5. Station Five: Vacuuming/Nitrogen Filling

This is the core function station. The vacuum chamber is pressed down to remove all air from the bag.

If nitrogen filling for preservation is required, nitrogen gas at a certain pressure is filled in after vacuuming, and then the bag is sealed.

6. Station Six: Heat Sealing

The vacuumed/nitrogen-filled bag opening is heated and pressurized to complete the seal. This is a crucial step in ensuring the product's shelf life.

7. Station Seven: Cooling (Optional)

The heat-sealed opening is cooled and shaped to ensure a firm and aesthetically pleasing seal.

8. Station Eight: Finished Product Output

The packaged beef jerky bags are released and conveyed out via conveyor belt to the next process (such as boxing, coding, and cartoning).

III. Core Advantages of the Eight-Station Beef Jerky Packaging Machine

1. High-end Packaging: Using pre-made bags, it can produce flat bags, stand-up pouches, zipper bags, and irregularly shaped bags, etc., with a very exquisite appearance, greatly enhancing the product's grade, making it very suitable for branding and the gift market.

2. Perfect Preservation Capability: Easily achieves vacuuming and nitrogen filling, effectively preventing oxidation, spoilage, and rancidity of beef jerky, significantly extending shelf life and maintaining optimal flavor.

3. Adaptable to Large Products: Automatic vertical packaging machines struggle to handle large, irregularly shaped pieces of beef jerky, such as large sheets or strips, while the eight-station bag-feeding packaging machine (whether manually fed or handled by a dedicated robotic arm) can handle them with ease.

4. High Degree of Automation: Full automation from bag picking to finished product output greatly reduces reliance on manual labor and improves the stability and consistency of production efficiency.

5. Good Flexibility: Relatively easy to change packaging bags of different sizes and shapes, suitable for producing a variety of products in multiple specifications.

Machine Specification:

| Item | ZC-X8200 | ZC-X8250 | ZC-X8300 |

| Packing speed | MAX 60 bags/min,depending on the quality of the packaging film,packaging materials packaging weight etc. | ||

| Bag size | (L)100-300mm (W)70- 200mm | (L)100-350mm (W)130- 250mm | (L)150-450mm (W)200-300mm |

| Bag type | Pre-mede bags,Stand-up bag,four-side sealed bag,three-side sealed bag,special-shaped bag | ||

| Weighing range | 10g-1kg | 10g-2kg | 10g-3kg |

|

Measurement accuracy |

*≤±0.5~1%, depending on the measuring equipment & materials. | ||

| Maximum bag width | 200mm | 250mm |

300mm |

| Gas consumption | 0.8Mpa 0.3m3/min (Supply by user) | ||

| Total Powder/Voltage | 2.5KW 380V 50/60Hz | 2.5KW 380V 50/60Hz | 3.7KW 380V 50/60Hz |

| Air compressor | Not less than 1CBM | ||

| Dimension | L1900*W1400*H1450 | L1900*W1400*H1450 | L2000*W1500*H1550 |

| Machine Weight | 1300kg | 1400kg | 1500kg |

| Work flow | Giving bag→Coding→Opening bag(or Open zipper bag)→Filling→ Auxiliary→Exhaust→Heat sealing→Forming and output products. | ||

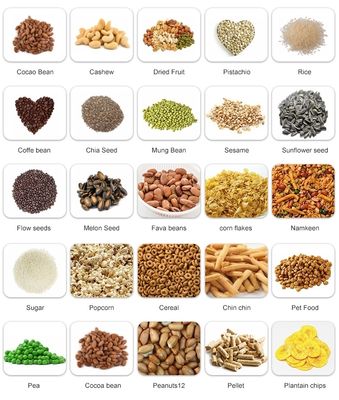

| Applicable scope | Granular type: crystal monosodium glutamate, granular drug, capsule, seeds, chemicals, sugar, chicken essence, melon seeds, nut, pesticide, fertilizer, etc | ||

(We can provide you with exclusive customized services according to your needs!)

![]()

![]()

![]()

![]()